SIGRACET® Fuel Cell Components

SGL Carbon develops and commercializes carbon-based products for Polymer-Electrolyte-Membrane Fuel Cells (PEMFC) :

-

Gas Diffusion Layers (GDL)

-

Foils used as separator plates for fuel cells and redox-flow batteries (Expanded Graphite)

SGL Carbon's Gas Diffusion Layers (GDL)

GDLs are typically designed as a bilayer structure consisting of a macro-porous backing material (carbon fiber paper support) and a micro-porous, carbon-based layer (MPL). The fibrous backing material governs the mechanical properties of the GDL (behavior upon compression, bending and shear strength, etc.) while the MPL ensures intimate contact to the catalyst layers, protects the delicate proton exchange membrane against perforation and plays an active role with respect to the water management in the cell during operation. There is consensus that this heterogeneous porosity brought about by this structure (hydrophilic/hydrophobic and various pore sizes) is advantageous for the performance.

Sketch of the bilayer structure of Gas Diffusion Layers

Sketch of the bilayer structure of Gas Diffusion Layers

Hydrophobic properties in the backing and the MPL are maintained by adding defined amounts of polytetrafluoroethylene (PTFE) to both sublayers. Various types of carbon particles (carbon blacks, graphite) can be used in the MPL in order to produce different levels of hydrophobicity. Furthermore, the MPL can be used as substrate to deposit catalyst particles for the manufacture of gas diffusion electrodes (GDEs).

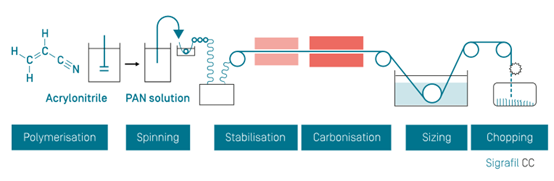

SGL Carbon has been producing fully-treated SIGRACET® gas diffusion layers by reel-to-reel processes since 1999. Carbon paper-type (prepared by wet-laying of chopped PAN-based carbon fibers) gas diffusion layers are the preferred solution since they can be manufactured at high volumes (scalability) and low thickness. The following figures show the whole value chain of GDL manufacturing. All commercially available GDL materials to date are based on carbon fibers derived from polyacrylonitrile (PAN). PAN (co)polymers are processed into precursor fibers by wet-spinning. Subsequent stabilization and pyrolysis yields high tensile (HT) carbon fibers which are sized and chopped to enable suitable processing by means of papermaking technologies.

Carbon Fiber Production

Manufacturing of SIGRAFIL® chopped carbon fibers

A primary carbon fiber web is laid by a papermaking technology and subsequent thermobonding. Thereafter, the obtained raw paper is impregnated with carbonisable thermoset resins (with optional addition of carbon fillers), cured and re-carbonized/graphitized. This serves to enhance the mechanical stability and conductivity as well as to adjust the desired porosity level.

Carbon Paper Substrate

Manufacturing route of SIGRACET® (carbon paper-based) gas diffusion layer backings

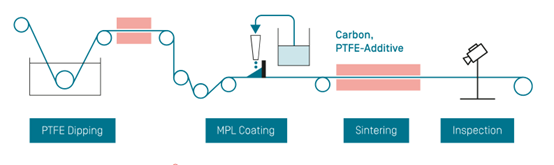

Finishing of GDL comprises hydrophobic treatment of the substrate with PTFE and coating with a microporous layer (MPL).

Finishing Treatment

Finishing treatments of SIGRACET® (carbon paper-based) gas diffusion layers

A loading of the substrate with 5% (w/w) PTFE has proven to be sufficient for obtaining a pronounced hydrophobicity. MPLs typically contain 20 to 25% PTFE. This MPL composition has been identified as the optimum ratio for PEMFC performance across a broad range of operating conditions. Mean pore diameters of SIGRACET® GDLs are typically in a range from 0.1 to 0.3 µm (Hg-Porosimetry) or 1.5 to 3 µm (calculated from capillary flow porometry). The hydrophobic treatment produces water repellent properties for the substrate and for the MPL (water contact angles by sessile drop method > 130°).

Typical properties of standard SIGRACET® GDL grades.

|

|

Unit |

22BB |

36BB |

|

Basic parameters |

|

|

|

|

Thickness |

µm |

215 |

280 |

|

Area weight |

g m-2 |

70 |

105 |

SIGRACET ®燃料电池组件

SGL Carbon 为聚合物-电解质-膜燃料电池 (PEMFC)开发和商业化碳基产品:

-

气体扩散层 (GDL)

-

用作燃料电池和氧化还原液流电池隔板的箔(膨胀石墨)

SGL Carbon 的气体扩散层 (GDL)

GDL 通常设计为双层结构,由大孔背衬材料(碳纤维纸载体)和微孔碳基层 (MPL) 组成。纤维背衬材料控制 GDL 的机械性能(压缩、弯曲和剪切强度等),而 MPL 确保与催化剂层的紧密接触,保护脆弱的质子交换膜免受穿孔,并在尊重方面发挥积极作用用于操作期间电池中的水管理。一致认为,这种结构(亲水/疏水和各种孔径)带来的这种异质孔隙率有利于性能。

气体扩散层的双层结构示意图

气体扩散层的双层结构示意图

背衬和 MPL 的疏水性通过在两个亚层中添加规定量的聚四氟乙烯 (PTFE) 来保持。MPL 中可使用各种类型的碳颗粒(炭黑、石墨)以产生不同水平的疏水性。此外,MPL 可用作沉积催化剂颗粒的基底,用于制造气体扩散电极 (GDE)。

自 1999 年以来,西格里碳素一直在通过卷对卷工艺生产经过全面处理的 SIGRACET ®气体扩散层。碳纸型(通过湿法铺设短切 PAN 基碳纤维制备)气体扩散层是首选解决方案,因为它们可以大批量(可扩展性)和低厚度制造。下图显示了 GDL 制造的整个价值链。迄今为止,所有市售 GDL 材料均基于源自聚丙烯腈 (PAN) 的碳纤维。PAN(共)聚合物通过湿法纺丝加工成前体纤维。随后的稳定化和热解产生高强度 (HT) 碳纤维,这些碳纤维经过上浆和切碎,以通过造纸技术进行合适的加工。

碳纤维生产

SIGRAFIL ®短切碳纤维

SIGRAFIL ®短切碳纤维

的制造

通过造纸技术和随后的热粘合铺设初级碳纤维网。此后,用可碳化的热固性树脂(任选添加碳填料)浸渍获得的原纸,固化并再碳化/石墨化。这用于提高机械稳定性和导电性以及调整所需的孔隙率水平。

碳纸基材

SIGRACET ®(碳纸基)气体扩散层背衬的

SIGRACET ®(碳纸基)气体扩散层背衬的

制造路线

GDL 的精加工包括用 PTFE 对基材进行疏水处理和用微孔层 (MPL) 进行涂层。

整理处理

SIGRACET ®(碳纸基)气体扩散层的

SIGRACET ®(碳纸基)气体扩散层的

精加工处理

事实证明,在基材上装载 5% (w/w) PTFE 足以获得明显的疏水性。MPL 通常含有 20% 到 25% 的 PTFE。这种 MPL 组合物已被确定为 PEMFC 在广泛的操作条件下性能的最佳比例。SIGRACET ® GDL 的平均孔径通常在 0.1 到 0.3 µm(Hg-Porosimetry)或 1.5 到 3 µm(根据毛细管流动孔隙度法计算)的范围内。疏水处理使基材和 MPL 具有防水性能(通过固着滴法得到的水接触角 > 130°)。

标准 SIGRACET ® GDL 牌号的典型特性。

|

|

单元 |

22BB |

36BB |

|

基本参数 |

|

|

|

|

厚度 |

微米 |

215 |

280 |

|

面积权重 |

通用-2 |

70 |

105 |

Polymer Electrolyte Membrane Fuel Cells (PEMFC)

Fuel cells have the potential to revolutionize energy conversion and distribution. Vehicle propulsion, stationary cogeneration of heat and electricity, and power supply in mobile applications are current focus areas of fuel cell technology.

Polymer Electrolyte Membrane Fuel Cells (PEMFC)

Fuel cells have the potential to revolutionize energy conversion and distribution. Vehicle propulsion, stationary cogeneration of heat and electricity, and power supply in mobile applications are current focus areas of fuel cell technology.

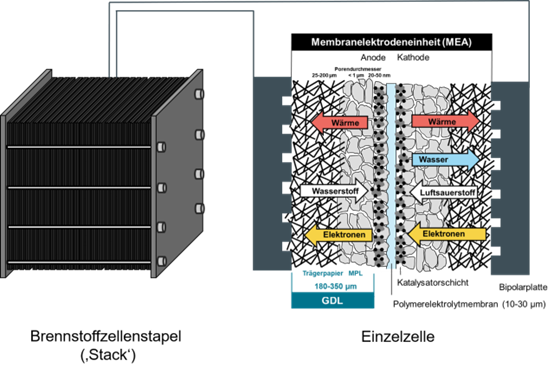

Gas diffusion layers (GDLs) are vital components in Polymer Electrolyt Membrane Fuel Cells (PEMFC) modulating all relevant transport processes comprising fuel, oxidants, reaction products, electricity and heat. Gas diffusion layers serve as a functional interface between the gas distribution compartments (structural cell parts, macroscopic scale) and the electrochemically active catalyst layers (reaction layers, processes occurring at the nanoscale). GDLs direct fuels and oxidants to the active sites whilst removing heat and reaction products and electrically wiring the reaction layers with the current collectors.

Sketch of a single cell of a fuel cells stack with gas diffusion layers (GDL)

Sketch of a single cell of a fuel cells stack with gas diffusion layers (GDL)

聚合物电解质膜燃料电池 (PEMFC)

燃料电池有可能彻底改变能量转换和分配。车辆推进、固定式热电联产以及移动应用中的电源是燃料电池技术的当前重点领域。

气体扩散层 (GDL) 是聚合物电解质膜燃料电池 (PEMFC) 中的重要组成部分,可调节包括燃料、氧化剂、反应产物、电和热在内的所有相关传输过程。气体扩散层充当气体分配室(结构电池部分,宏观尺度)和电化学活性催化剂层(反应层,发生在纳米尺度的过程)之间的功能界面。GDL 将燃料和氧化剂引导至活性位点,同时去除热量和反应产物,并将反应层与集电器电气连接。

具有气体扩散层 (GDL) 的燃料电池堆的单个电池的示意图

具有气体扩散层 (GDL) 的燃料电池堆的单个电池的示意图

https://www.sglcarbon.com/en/markets-solutions/material/sigracet-fuel-cell-components/

艾邦氢能产业链通讯录,目前有2200人加入,如亿华通、清极能源、氢蓝时代、雄韬、氢牛、氢璞、爱德曼、氢晨、喜马拉雅、明天氢能、康明斯、新源动力、巴拉德、现代汽车、神力科技、中船712等等,可以按照标签筛选,请点击下方关键词试试

资料下载:

艾邦氢能产业链通讯录,目前有2200人加入,如亿华通、清极能源、氢蓝时代、雄韬、氢牛、氢璞、爱德曼、氢晨、喜马拉雅、明天氢能、康明斯、新源动力、巴拉德、现代汽车、神力科技、中船712等等,可以按照标签筛选,请点击下方关键词试试

资料下载: