燃料电池用双极板的密封

在 ViscoTec 技术中心进行工艺优化点胶测试

当前,全球对环境兼容和高效移动的需求使燃料电池技术重新回到战略讨论的前沿。

同时,燃料电池和氢气前景广阔。从市场和技术成熟度来看,燃料电池应用的市场份额仍然很小,但已经获得了很大的发展势头。根据这一发展,最近在 ViscoTec 技术中心进行了点胶测试,使用 Wacker 有机硅密封燃料电池的双极板。

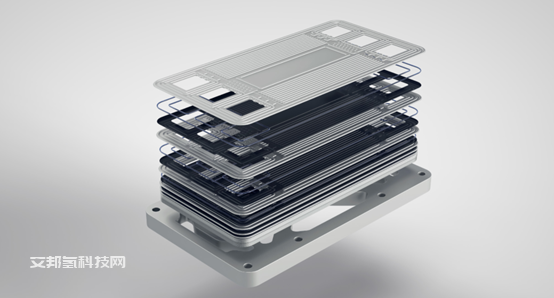

燃料电池堆的结构

点胶测试的目的:

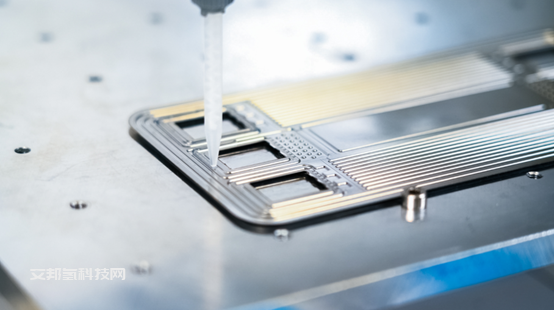

按照关于高度公差的精确规范将密封接缝应用于双极板上。通过此类测试,可以确定工艺参数并将风险降至最低——以便能够从中推断出持续改进措施。使用 2-component Dispenser P4/4 以 0.12 ml/s 的分配速度进行测试。没有超过密封胶珠的公差。密封珠的公差为 +/- 0.05 毫米——这已经是一个令人印象深刻的结果,点胶技术专家希望进一步改进。

燃料电池密封双极板点胶试验

系统设计适应客户的需求或相应应用的要求。例如,可以单独调整分配容量。作为工艺安全、精确和可扩展的点胶技术的系统供应商,ViscoTec 是各行各业广受欢迎的合作伙伴。在特殊业务开发部门的帮助下,ViscoTec 与研究机构、机器制造商和最终客户合作改进和自动化生产方法。ViscoTec 可以在这里发挥广泛的协同作用,但由于拥有自己的技术中心,它还可以进行广泛的试验并产生工艺知识。

在燃料电池领域,点胶专家也在支持市场的发展,希望让客户实现持续增长。行业专家认为,在这个未来的大众市场中,欧洲的销售额有望达到 650 亿欧元,而全球市场的销售额有望达到 650 亿欧元。1特别是中国、日本和韩国,还有美国,应被视为销售市场,以便继续保持国内公司目前的出口实力。为了挖掘氢能和燃料电池行业未来的增长潜力并在国际舞台上保持竞争力,在未来两到五年内,通过投资继续建立和扩大现有能力至关重要。

ViscoTec 随时准备提供主动支持并创造附加值。毕竟,如果目标是用于粘合或密封元件(例如双极板)的点胶,那么即使是小批量,也必须能够实现经济效益和技术准确性。因此,以适度的投资成本促进访问至关重要,而且通过深思熟虑的系统配置来确保可扩展性。特别是可扩展性和相关的成本递减必须为客户计算。

Sealing of bipolar plates for fuel cells

Feb 7, 2022 | Company news

Dispensing tests for process optimization in the ViscoTec technical center

The current, worldwide demand for environmentally compatible and efficient mobility brings fuel cell technology back to the forefront of strategic discussions.

At the same time, fuel cells and hydrogen promise large potential. Looking at the market and the maturity of the technology, it can be seen, that fuel cell applications still claim a small market share but have already gained a great deal of momentum. In line with this development, dispensing tests were recently carried out at the ViscoTec technical center using a Wacker silicone to seal bipolar plates for fuel cells.

The aim of the dispensing tests: To apply the sealing seam to a bipolar plate in compliance with precise specifications regarding height tolerance. Due to such tests, it is possible to determine process parameters and minimize risks – in order to be able to deduce continuous improvement measures from them. The test was carried out with the 2-component Dispenser P4/4, at a dispensing speed of 0.12 ml/s. The tolerance of the sealant bead was not exceeded. The tolerance of the sealing bead was +/- 0.05 mm – already an impressive result, which the dispensing technology experts want to improve even further.

The system design is adapted to the needs of the customer or to the requirements of the respective application. For example, the dispensing capacity can be adjusted individually. As a system supplier for process-safe, precise, and scalable dispensing technology, ViscoTec is a sought-after partner in a wide range of industries. With the help of special business development units, ViscoTec works together with research institutions, machine builders and end customers on improved and automated production methods. ViscoTec can draw on a wide range of synergies here, but thanks to its own technical center it can also carry out extensive trials and generate process knowledge.

In the fuel cell sector too, the dispensing experts are supporting the development of the market and want to enable customers to achieve continuous growth. Industry experts see a potential of EUR 65 billion in sales in Europe and a further EUR 65 billion in global markets in this future mass market.1 China, Japan, and South Korea in particular, but also the USA, should be considered as sales markets so that the current export strength continues to be maintained for domestic companies. In order to exploit the future growth potential of the hydrogen and fuel cell industry and to remain competitive in the international arena, it will be crucial in the next two to five years to continue to build up and expand existing competencies through investment.

ViscoTec is always ready to provide proactive support and create added value. After all, if dispensing for bonding or sealing components such as bipolar plates is the goal, economic benefits and technical accuracy must be possible even for small quantities. It is therefore crucial to facilitate access with moderate investment costs, but also to ensure scalability by means of a well-thought-out system configuration. Particularly scalability and the associated cost degression must be calculable for customers.

https://www.viscotec.de/en/sealing-of-bipolar-plates-for-fuel-cells/

艾邦氢能产业链通讯录,目前有2200人加入,如亿华通、清极能源、氢蓝时代、雄韬、氢牛、氢璞、爱德曼、氢晨、喜马拉雅、明天氢能、康明斯、新源动力、巴拉德、现代汽车、神力科技、中船712等等,可以按照标签筛选,请点击下方关键词试试

资料下载:

艾邦氢能产业链通讯录,目前有2200人加入,如亿华通、清极能源、氢蓝时代、雄韬、氢牛、氢璞、爱德曼、氢晨、喜马拉雅、明天氢能、康明斯、新源动力、巴拉德、现代汽车、神力科技、中船712等等,可以按照标签筛选,请点击下方关键词试试

资料下载: